18. 08. 2022

Last year was marked by challenges. A major challenge was a complex project to optimize the material flow in WITTE AUTOMOTIVE, which manufactures and distributes handles for the automotive industry.

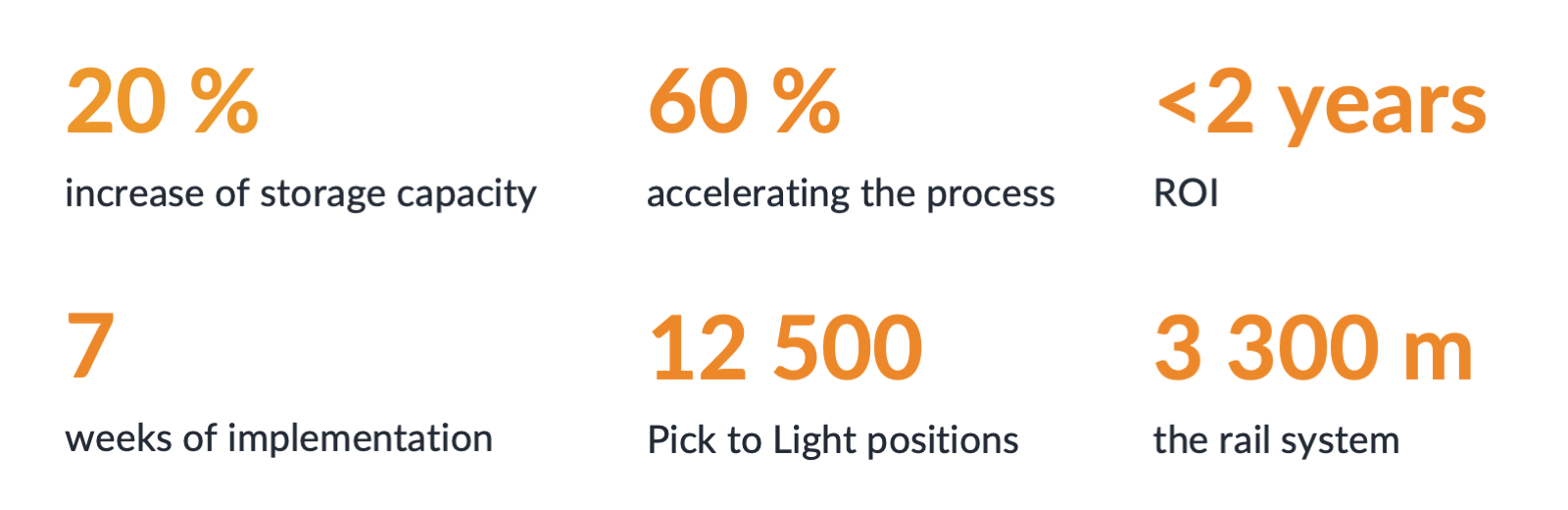

The aim of the project was the complete transformation of the central pallet warehouse, beacuse its solution was very inefficient in terms of storage capacity and material handling.

Description of the solution

In the central warehouse, we installed a rail storage on the ground called "Flat storage", equipped with Pick to Light (light navigation). The main reason why the customer chose our technology to optimize the material flow was the pressure to reduce costs and the shortage of workers on the labor market.

The overall concept of the solution is very simple and tailor-made to the customer's needs. The warehouse also includes Pick to Light racks designed for storing low-turnover parts or work-in-progress material. Their main advantage is the SMART modular tubular system, which allows the racks to be assembled in different dimensional configurations. Simple assembly allows racks to be assembled directly at the customer's site or delivered fully assembled ready for immediate start-up. Witte now assembles its new racks in-house.

Video

Partners

Are you interested in our solution? Do not hesitate to contact us!