05. 04. 2022

The environmental aspect is clearly becoming the most important factor today. The main idea of the future, i.e. achieving a minimal carbon footprint in the transport of packaging using electric vehicles, is contributing significantly to the growing trend of returnable packaging, which is our primary focus. The most environmentally friendly solution is to ensure that returnable packaging has the longest possible lifetime and is subsequently 100% recyclable. For example, polypropylene is suitable for this. In practice, it seems that if the packaging is made of a combined material, such as polypropylene and metal components, it is much more difficult to recycle. Therefore, the ideal solution is to design a foldable packaging from as few materials as possible. The energy consumption ratio remains negligible when producing the same type of packaging in both folding and rigid solutions and the lifetime of both packaging options is comparable. However, the economic aspect of transport distances has to be taken into account. Semi-finished products in the form of foams, sheets and textiles are used for the production of protective equipment for transported products. Returnable folding packs primarily complement textile dividers because of their easy foldability. In this respect too, however, the uniformity of the materials used is an important parameter.

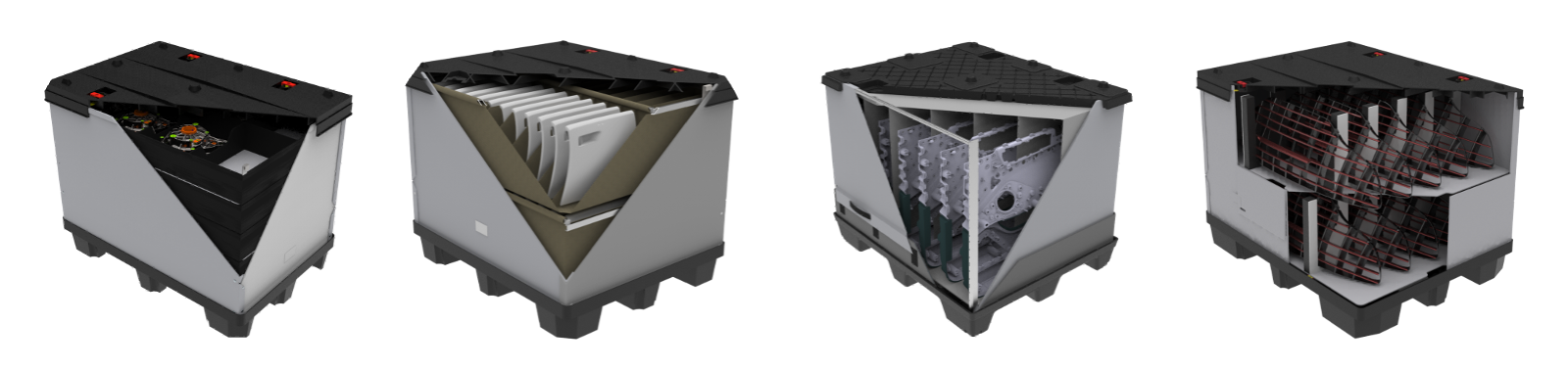

Multi-purpose packaging

- Foldable/ collapsible (for return transport) → multiple materials often need to be combined

- Non-folding/ rigid → easier design and sustainability of the uniformity of the material used

Which products are the most demanding in terms of protection and why?

The level of protection required depends on the sensitivity of the surface and the dimensional stability of the transported product. In the automotive industry, the most challenging in terms of protection appears to be the transport of painted parts. From the perspective of Industry 4.0, the demand for precise positioning of individual parts is increasing, among other things, as a result of robotic production processes.

What are the most common customer requests and how have they evolved in recent years?

Customer requirements are closely linked to current trends. These include the lifetime of the packaging, its recyclability and related services. In the case of multi-purpose packaging, great emphasis is also placed on maximizing the returnable ratio (under which we can imagine the effort to have the smallest possible volume of packaging after its folding) and handling, i.e. the difficulty of readjusting the returnable packaging to a state that guarantees the maximum returnable ratio.

Is price still the most important factor, or what feature is decisive?

Unfortunately, price is still the number one priority for most of our customers. The requirements for the universality of customer packaging solutions are also constantly increasing.

Furthermore, the factors mentioned above are decisive:

- Package life

- Recyclability of packaging and related services

- Maximizing the return ratio

- Handling for readjusting the returnable packaging to a state guaranteeing the maximum return ratio